PVC Pipes and Fittings: Know The Use, Production And The Exceptions

Durga PVC pipe & fittings are absolutely one of the all around known and adaptable sorts of plastic piping. These kinds of pipes have been utilized for more than 80 years with the support of a huge number of utilizations in various market areas across the globe. These pipes are incredibly solid and sturdy when contrasted with metal piping. Likewise, they accompany total consumption opposition alongside little danger of capitulating to warm extension or constriction now and again.

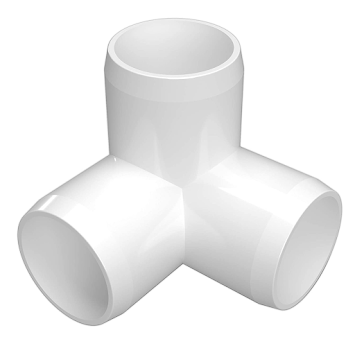

These pipes come in different shapes and sizes with a wide scope of accessible fittings while being practical and strong simultaneously. Contingent upon the sort of PVC variation, these can be utilized for both cold and warm water.

What is the utilization of PVC Pipes and Fittings?

The best PVC pipe manufacturers make PVC pipes which are generally utilized for making sewage pipes, water mains and furthermore water systems. These have extremely dependable properties and are very simple to introduce. With being light in weight, solid, strong and recyclable, these are very modest and feasible as well.

These pipes have an exceptionally smooth surface which in some way or another empowers quicker water stream due to the lower measures of rubbing than the pipes which are produced using different materials like cast iron or cement. These pipes are made by the pipe makers in different sorts of lengths, divider thicknesses and breadths, as per distinctive measuring principles.

Assembling of the PVC Pipes

The Pipe Manufacturers Company make the PVC pipes by expulsion of unrefined substance PVC with following the very advances that are utilized in commonplace pipe expulsion tasks:

1. By taking care of unrefined substance pellets/powder into the PVC twin screw extruder.

2. By liquefying and warming it in different extruder zones.

3. Then expelling through a bite the dust for providing it with the state of a pipe.

4. Then the molded pipe is cooled.

5. At the end the PVC pipes are sliced to the ideal length.

Nonetheless, despite the fact that having a similar assembling interaction to most plastic piping, PVC pipes have some inherent qualities that offer extra difficulties to the pipe makers as far as both creation and simultaneously situating their items available.

What are the Challenges of PVC Pipe Manufacturing?

The principle challenge of PVC pipe fabricating is the Increased Extruder Friction.

Taking a gander at the idea of PVC plastic, the extruders of PVC are inspired by high measures of erosion and stress. This by and large implies that to offer a long life as far as administration, these pipes require the utilization of a unique extruder that includes a twin screw extruder arrangement, alongside highlighting hearty development materials that have the ability to withstand the unforgiving PVC extruder working conditions and changes.

If you’re looking for any of the best pipes and fittings around Bihar, Jharkhand and UP, then head to Durga Electroplast for having an amazing range of plastic piping. Make your home a dream home with the tremendous collection of Durga.

Comments

Post a Comment